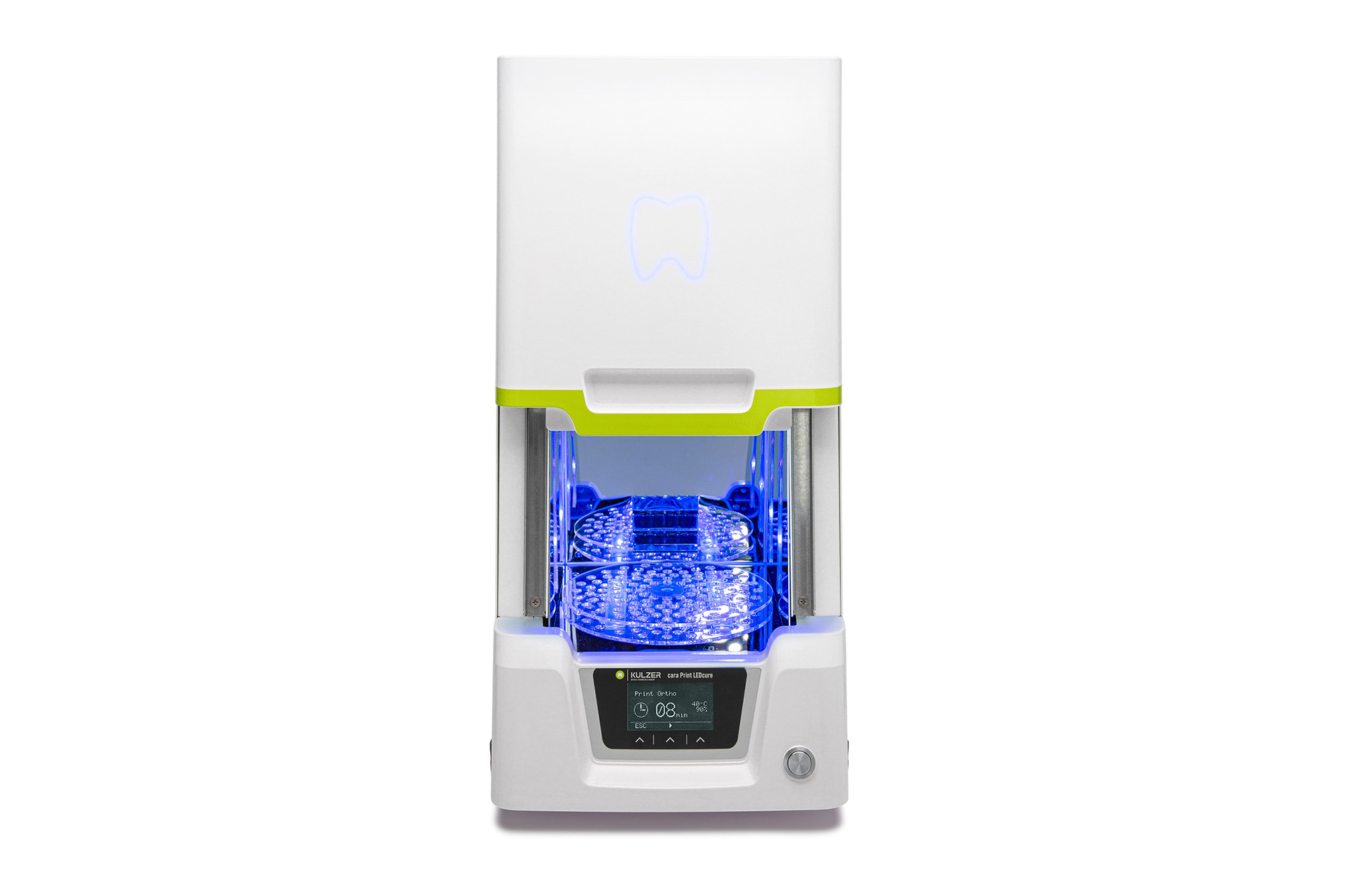

cara Print LEDcure

Overview

cara Print LEDcure offers the flexibility to set the time, temperature and LED intensity to ensure optimal illumination conditions for all opaque & transparent 3D print materials.

cara Print LEDcure features long-life LEDs for both 385 and 405nm resins, a transparent turntable so there’s no need to flip objects, and a fan-assisted heater. All this creates a stable thermal environment for more complete bond formation and excellent mechanical properties in terms of flexural strength, elongation at break, edge strength and color stability – and restorations won’t come out sticky.

Laboratories using our dima Print materials will find preset illumination programs for quick, yet dependable results. The device also allows for more than 100 additional customizable programs for post-curing other 3D resins.

Benefits

Cover all your post-curing needs in a reliable, yet simple process

- Flexible: individually set time, temperature & intensity for all 3D resins

- Large chamber (fits 4-5 models) with long-life LEDs

- Optimal illumination conditions for all opaque & transparent 3D print materials (385 and 405 nm resins)

- Ideal, homogeneous curing, no flipping, objects not “sticky” after curing

- Factory-set programs (time, intensity, temp.) for dima Print materials & storage for 100+ programs for other materials

- Fan-assisted heater for more complete bond formation & optimal mechanical properties

- Made in Germany incl. CE and cUL

Good to know

Features

- Pre-set illumination programs for dima Print materials

- Space for 100+ user-set programs

- Homogeneous curing

- Individually set time, temperature & LED intensity

- All opaque and transparent 385 & 405 nm resins

- Dedicated wavelengths and active heating especially for 3D printing

- Big curing chamber with transparent turntable for e.g. 4-5 models

- No distortion also of bigger objects and no manual turning needed

- No flipping, objects never sticky

Applications

See it from every angle! Click on the image to see a 360° view of cara Print LEDcure.

Specifications

| Technical details | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Unit size (W x D x H) | 250 x 350 x 380 mm (550 mm high with open door) | |||||||||||||

| Unit weight | 12.8 kg | |||||||||||||

| Illumination chamber dimensions (W x D x H) | 170 x 200 (at base) x 170 mm | |||||||||||||

| Transparent rotating plate diameter | 150 mm ∅ (= usable space) | |||||||||||||

| Light source | IEC Class I | |||||||||||||

| Illumination source | 10 LED modules w/ 5 LEDs with 3 watt each (= 150 Watt LED power) | |||||||||||||

| Program settings | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature range | 30 – 80°C Note: can be operated with no heating | |||||||||||||

| Time range | 1 – 30 minutes | |||||||||||||

| Intensity | 10 – 100 % (i.e. 15 – 150 LED illumination intensity) | |||||||||||||

| Warranty | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Warranty | 1 year warranty for customers worldwide | |||||||||||||

Downloads

Catalog Prices

In stock

Only %1 left

A 3D printing process that improves the efficiency and profitability of dental labs. It ranges from indication-specific resins and a 3D printer, to hands-free part washing and light-curing.